27

Jul

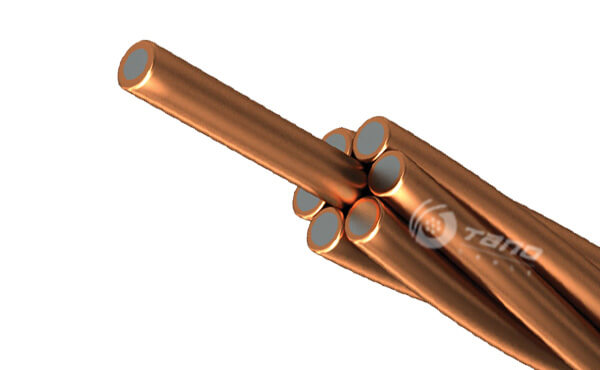

The introduction of copper clad steel(CCS)

Share:

Copper Clad Steel is the ideal solution for grounding wire for power type applications. Composed of a steel core with copper cladding, the steel wire gives the wire its strength and the consistent layer of copper provides electrical conductivity and resistance to corrosion. The process temperature and pressure ensure a uniformly bonded and tightly adherent copper coating. The nominal thickness of copper is 6.5% of the radius of the wire.

To manufacture Copperclad Steel Wire, carbon steel (low, high strength and extra high strength) is bonded with a uniform layer of oxygen-free coppercladding to achieve 21%, 30% and 40% IACS (International Annealed Copper Standard) conductivities. The material is available in a single wire, 3, 7, 19 and 37 strands.

The properties of copper-clad aluminium wire include:

. Less expensive than a pure copper wire

. Lighter than pure copper

. Higher electrical conductivity than pure aluminium

. Higher strength than aluminium

. Electrical connections are typically more reliable than pure aluminium

. Typically produced as a 10% or 15% by copper volume product

Welcome to your inquiry for CCS.

To manufacture Copperclad Steel Wire, carbon steel (low, high strength and extra high strength) is bonded with a uniform layer of oxygen-free coppercladding to achieve 21%, 30% and 40% IACS (International Annealed Copper Standard) conductivities. The material is available in a single wire, 3, 7, 19 and 37 strands.

The properties of copper-clad aluminium wire include:

. Less expensive than a pure copper wire

. Lighter than pure copper

. Higher electrical conductivity than pure aluminium

. Higher strength than aluminium

. Electrical connections are typically more reliable than pure aluminium

. Typically produced as a 10% or 15% by copper volume product

Welcome to your inquiry for CCS.

Previous article:

Next article: