FAQ

-

QWhat is VCB?AVCB(Vacuum circuit breaker) is an electrical switching device mainly used in power systems. It can quickly cut off the current when a circuit fault occurs, thereby protecting the circuit and equipment from damage. Vacuum circuit breakers are named because both the arc extinguishing medium and the insulating medium of the contact gap after arc extinguishing are high vacuum. Its core characteristics include small size, light weight, suitable for frequent operation and no maintenance.

Working principle

The main working principle of vacuum circuit breakers is to cut off the current by removing the arc energy from the circuit breaker contacts. When the contacts of the circuit breaker are opened in a vacuum, an arc is generated, but due to the high insulation strength of the vacuum, the arc is easily extinguished. The ions, metal vapors and electrons in the arc can quickly condense above the contact surface area, thereby increasing the strength of the dielectric.

Application

Vacuum circuit breakers are widely used in indoor power distribution devices in 3 to 10kV, 50Hz three-phase AC systems. They are particularly suitable for industrial and mining enterprises, power plants and substations as protection and control of electrical equipment. Due to their oil-free and low maintenance characteristics, vacuum circuit breakers perform well in places where frequent operation is required.

Advantages

Small size and light weight: easy to install and maintain.

Suitable for frequent operation: no frequent maintenance is required, reducing maintenance costs.

Oil-free design: avoids safety hazards such as oil leakage or fire.

Structural composition

The important components of vacuum circuit breakers include pull rods, flexible connections, terminals, vacuum indicators, operating rods, locking cams, circuit breaker springs, main connections, load springs and support insulators. -

QWhat is RUM?ARUM (Ring Main Unit) is a switchgear used in secondary power distribution systems, mainly used between distribution substations and end consumers to ensure continuous power supply and isolate the faulty part from the network. The basic components of the ring main unit include circuit breakers, load break switches, fuses, grounding switches, busbars and metering units, etc. These components work together to achieve functions such as circuit control, isolation and protection.

Main functions

Circuit control: The ring main unit is used to switch the circuit from one feeder to another in the circulating network.

Isolation: Separate the faulty part from the rest of the circuit to ensure the stable operation of the system.

Protection: Provide overload, short circuit or ground fault current protection through circuit breakers, fuses and other devices.

Application

Ring main units are widely used in urban and industrial areas, especially in places where continuous power supply is required. It is often used in distribution stations and box-type substations in load centers such as urban residential areas, high-rise buildings, large public buildings, factories and enterprises. The ring main unit has a simple structure, small size and low price, which can improve power supply parameters and performance and ensure power supply safety.

Types and characteristics

According to the insulating medium used, the ring main unit can be divided into the following types:

1. Air insulated ring main unit: simple structure, easy maintenance, suitable for residential areas, small factories and commercial buildings.

2. Gas insulated ring main unit: small size, light weight, suitable for occasions requiring high reliability and compact design.

3. Gas insulated cabinet: gas insulation is used, the size is greatly reduced, it is not affected by the environment, and is often used in the main distribution system. -

QWhat is AIS?AAIS(Air Insulated Switchgear) is a traditional open-type electrical equipment. The busbar of AIS equipment is directly exposed to the air, relying on air and insulators to isolate the live parts from the ground and the insulation between phases.

Main components

Circuit breaker: used to cut off or connect the circuit.

Voltage transformer: used to measure voltage.

Current transformer: used to measure current.

Isolating switch: used to isolate the power supply.

Lightning arrester: protect the equipment from lightning strikes.

Ice melting switch: selected according to the local ice cover conditions, used to prevent the equipment from freezing.

Advantages:

1. Low price: Compared with GIS equipment, the initial investment cost of AIS equipment is lower.

2. Easy maintenance: On-site maintenance is relatively easy, and subsequent expansion intervals are convenient.

3. Clear layout: The equipment layout is clear, which is convenient for daily maintenance and overhaul.

Disadvantages:

1.Low safety: Multiple live parts of the equipment are exposed to the outside, which is less safe.

2.Large maintenance workload: More maintenance work is required.

3.Long construction period: The construction period is long, the area occupied is large, and it is easily affected by weather factors.

Application

AIS equipment is widely used in scenarios such as new energy power generation projects and power grid substations. In new energy power generation projects, due to the small number of inlet and outlet line intervals, the price advantage of AIS equipment is not obvious, but in power grid substations, due to the large number of inlet and outlet line intervals, the price advantage of AIS equipment is more obvious, so it is widely used. -

QWhat is GIS?AGIS (Gas Insulated Switchgear) is a gas-insulated fully enclosed switchgear, which usually uses SF6 gas as the insulating medium and integrates high-voltage components such as circuit breakers, disconnectors, grounding switches, busbars, current transformers, voltage transformers, and lightning arresters.

Main functions

The main function of GIS equipment is to serve as a primary device in a substation to control and manage the current and voltage of the power system. It is enclosed in a metal grounded shell and filled with SF6 gas at a certain pressure to ensure the insulation and arc extinguishing ability of the equipment.

Advantages

GIS equipment has the following advantages:

1.Small footprint: Due to the excellent insulation properties of SF6 gas, GIS equipment can greatly reduce the size of the substation.

2.High reliability: The live parts are sealed in inert SF6 gas, which improves the reliability of the substation.

3.Good safety: The live parts are enclosed in a grounded metal shell, reducing the impact of the external environment on the equipment.

4.Low maintenance workload: The fully enclosed structure reduces the impact of the external environment, has a long maintenance cycle, and has low maintenance workload.

Disadvantages

Although GIS equipment has many advantages, it also has some disadvantages:

1.Complex single maintenance: Due to the fully enclosed structure, once a fault occurs, the maintenance work is relatively complicated.

2.Lack of detection means: Currently, the detection means of GIS equipment are relatively poor, which increases the difficulty of maintenance.

3.Environmental erosion problem: If the enclosed structure is eroded and damaged by the external environment, it may cause water ingress, air leakage and other problems. -

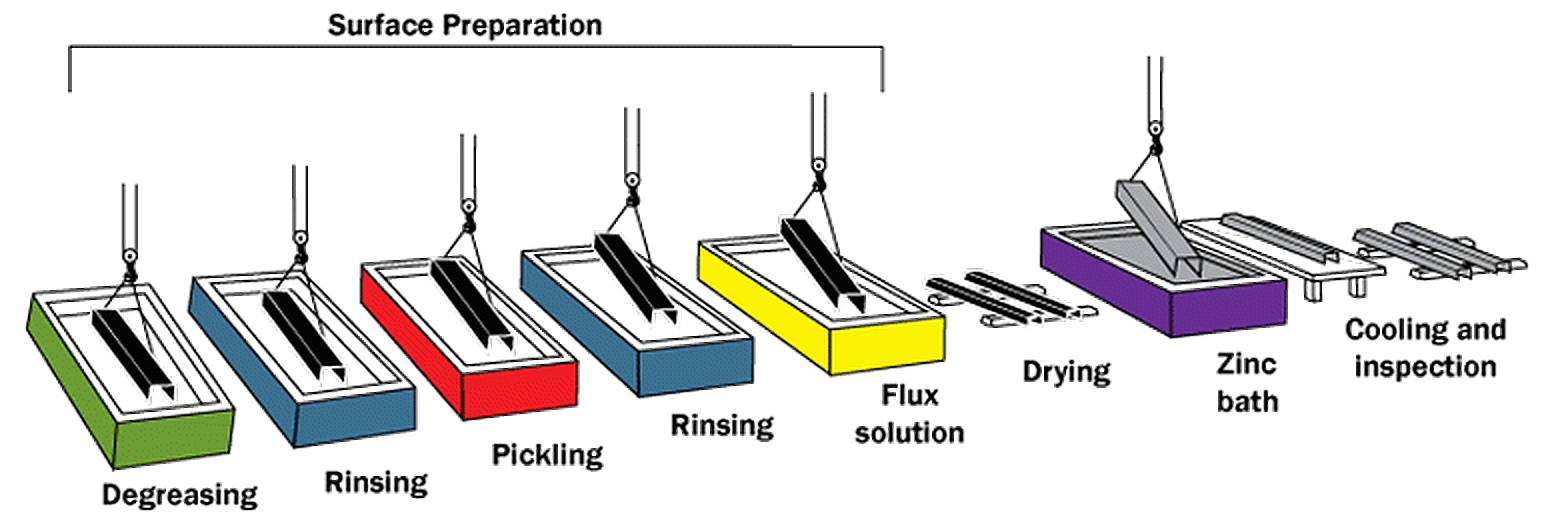

QWhat is Hot-Dip Galvanizing?AHot-dip galvanizing (HDG) is the process of coating fabricated steel by immersing it in a bath of molten zinc. There are three fundamental steps in the hot-dip galvanizing process; surface preparation, galvanizing, and inspection (Figure 1).

(Figure 1)

Surface Preparation

When the fabricated steel arrives at the galvanizing facility, it is hung by wire or placed in a racking system which can be lifted and moved through the process by overhead cranes. The steel then goes through a series of three cleaning steps; degreasing, pickling, and fluxing. Degreasing removes dirt, oil, and organic residues, while the acidic pickling bath will remove mill scale and iron oxide. The final surface preparation step, fluxing, will remove any remaining oxides and coat the steel with a protective layer to prevent any further oxide formation prior to galvanizing. Proper surface preparation is critical, as zinc will not react with unclean steel.

Galvanizing

After surface preparation, the steel is dipped in the molten (830 F) bath of at least 98% zinc. The steel is lowered into the kettle at an angle that allows air to escape from tubular shapes or other pockets, and the zinc to flow into, over, and through the entire piece. While immersed in the kettle, the iron in the steel metallurgically reacts with the zinc to form a series of zinc-iron intermetallic layers and an outer layer of pure zinc.

Inspection

The final step is an inspection of the coating. A very accurate determination of the quality of the coating can be achieved by a visual inspection, as zinc does not react with unclean steel, which would leave an uncoated area on the part. Additionally, a magnetic thickness gauge can be used to verify the coating thickness complies with specification requirements.

.png)

(Figure 2)

Coating Benefits

Hot-dip galvanizing provides a number of benefits to the steel it protects. The metallurgically-bonded zinc-iron alloy layers not only create a barrier between the steel and the environment, but also cathodically protect the steel. The cathodic protection offered by zinc means the galvanized coating sacrifices itself to protect the underlying base steel from corrosion.

The tightly adhered coating, which has bond strength of around 3,600 psi, is also extremely abrasion-resistant, as the intermetallic layers are harder than the base steel (Figure 2). However, even if the coating is damaged, zincs sacrificial action will protect exposed steel up to ¼ inch away.

In addition to the cathodic protection offered by hot-dip galvanizing, there are a few other characteristics of the coating which provide longevity. First, reaction in the galvanizing kettle is a diffusion process, which means the coating grows perpendicular to the surface, ensuring all corners and edges have at least equal thickness to flat surfaces. Furthermore, the complete immersion in the zinc bath provides total coverage of the steel, including the interior of hollow structures.

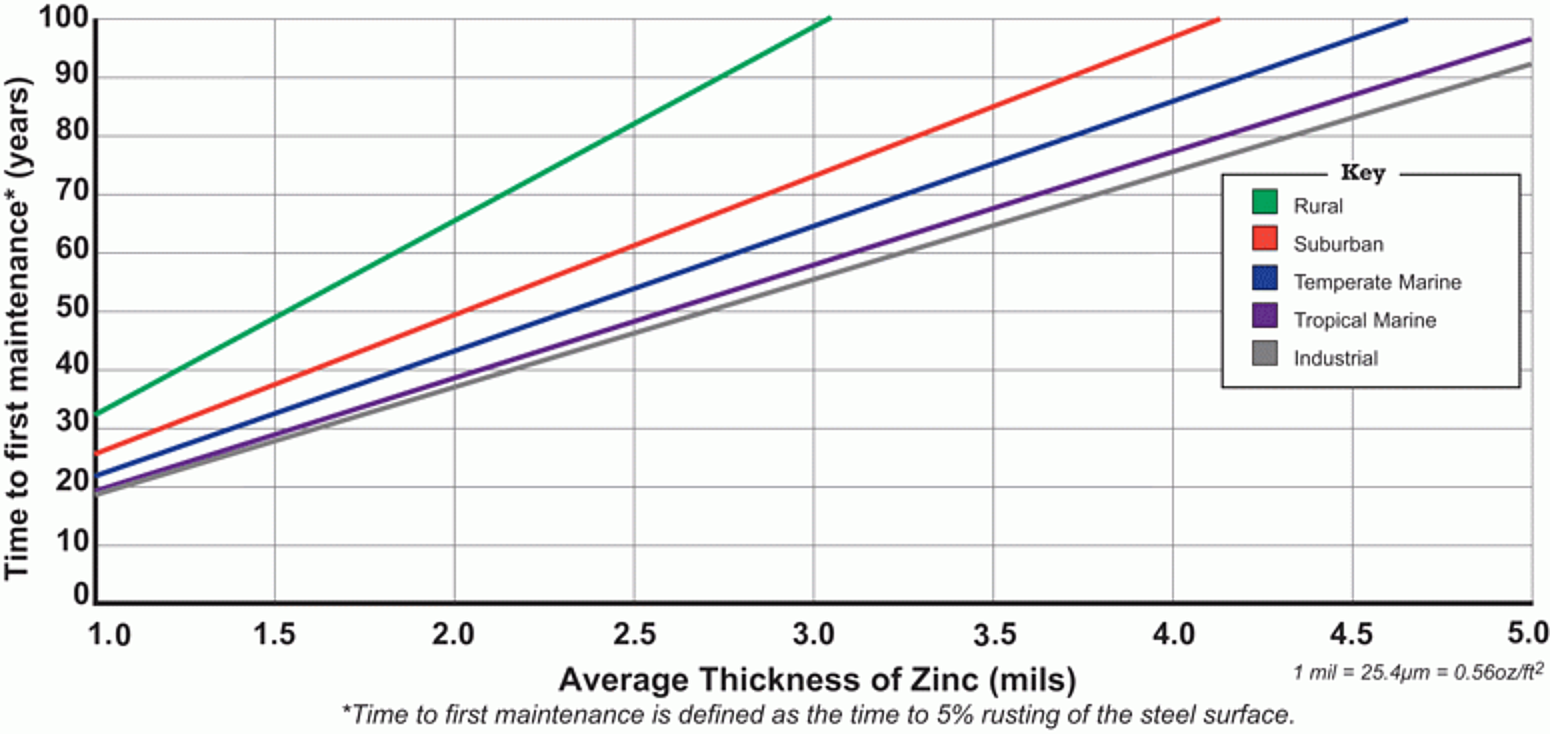

Finally, the zinc coating naturally develops an impervious layer of corrosion products on the surface, know as the zinc patina. The patina, cathodic protection, complete coverage and all of these other features, provide hot-dip galvanized steel with a long, maintenance-free service life. Thjavascript:void(null);e time to first maintenance for hot-dip galvanized steel can be seen in Figure 3.

(Figure 3) -

QWhat are the differences between DC and AC?A1. Different concepts

AC stands for alternating current, which refers to current whose direction and magnitude change periodically over time. Simply put, alternating current changes direction many times in one cycle.

DC stands for direct current, which refers to current whose direction and magnitude remain constant. The current of direct current flows in only one direction, so its voltage is also constant.

2. Different working principles

The working principle of AC is based on Faraday's law of electromagnetic induction. When a coil rotates in a magnetic field, an induced electromotive force is generated in the conductor, thereby generating alternating current. Since the rotational motion is periodic, the direction of the generated current will also change periodically, which is the characteristic of alternating current. In the power grid, the generator generates alternating current through a rotating magnetic field, and changes the voltage through a transformer, and finally transmits it to the user end.

The working principle of DC is relatively simple. When the power supply provides a constant voltage difference, the current will flow from the positive pole of the power supply to the negative pole in a fixed direction. The battery is the most common DC power supply, which generates a constant current through a chemical reaction. Since the DC current does not change direction, it can be directly used to drive various electrical equipment.

3. Different applications

Typical applications of AC:

Home power grid: Most households use AC power. Electrical appliances such as lighting, air conditioning, and refrigerators all rely on AC power.

Industrial production: Many industrial equipment, such as motors and welding machines, are driven by AC power.

Power transmission: AC power is transmitted to distant users through high-voltage transmission lines, and then stepped down by transformers for users to use.

Typical applications of DC power:

Electronic devices: Most portable electronic devices, such as mobile phones, laptops, tablets, etc., use DC power.

Electrical vehicles: Batteries of electric vehicles and electric bicycles provide DC power to drive motors.

Energy storage system: Photovoltaic panels in solar power generation systems generate DC power, which is stored in batteries and then converted to AC power for home use through inverters.

4. Advantages and disadvantages

Advantages of AC:

Easy to transmit: AC power can be easily stepped up and down by transformers, so that power can be effectively transmitted to long distances.

Mature power generation technology: AC power generation technology is relatively mature, with low cost, and suitable for large-scale power generation.

Strong grid compatibility: Most power systems in the world use alternating current, which has wide compatibility.

Disadvantages of AC:

Complexity: Since the frequency and phase of AC need to be precisely controlled, the design and maintenance of the power system are relatively complex.

Energy loss: AC will generate induced current during long-distance transmission, resulting in energy loss.

Advantages of DC:

High stability: The voltage and current of DC are constant, not affected by external electromagnetic interference, and suitable for use in electronic devices.

Convenient energy storage: DC can be directly stored in batteries, which is convenient for mobile and portable devices.

High energy transmission efficiency: DC has higher transmission efficiency under certain specific conditions, such as in high-voltage direct current (HVDC) systems.

Disadvantages of DC:

Difficult conversion: It is relatively difficult to increase and decrease the voltage of DC, and complex power electronic equipment is required.

Limited application: Since the global power grid is mainly based on AC, the applications of DC are relatively limited.